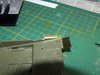

Next to hit the bench is this oldy.

View attachment 306903

After saying how much I don't like PE in the Luchs build, I have a nice little lot of PE coming up.

View attachment 306904

I will be stealing an idea from an old MM member when he built this beast with all the PE, glue the PE to styrene strips and then stick that to the model. Also a shout out to anybody that has built the RB models gun, I've had a practice of putting it together but there are a couple of pieces I just can't work out where they go, so any help or advice is greatly appreciated.

I'll get some sprue shots up as soon as possible.

cheers

Ross

View attachment 306903

After saying how much I don't like PE in the Luchs build, I have a nice little lot of PE coming up.

View attachment 306904

I will be stealing an idea from an old MM member when he built this beast with all the PE, glue the PE to styrene strips and then stick that to the model. Also a shout out to anybody that has built the RB models gun, I've had a practice of putting it together but there are a couple of pieces I just can't work out where they go, so any help or advice is greatly appreciated.

I'll get some sprue shots up as soon as possible.

cheers

Ross