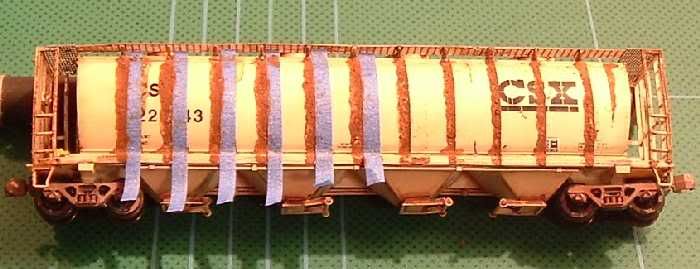

Just a rambling late night idea. The awesome real rust on tiking's models got me thinking.

As most of you know, plastics can be chrome plated. I wondered if anyone had any knowledge about the possibillity of plating plastic with steel or a metal that corodes in a similar way. This would take one hell of a lot of weathering work out of the build. I mean plate the plastic, dunk in vinegar....voila!

Probably not doable but i thought i would ask..

As most of you know, plastics can be chrome plated. I wondered if anyone had any knowledge about the possibillity of plating plastic with steel or a metal that corodes in a similar way. This would take one hell of a lot of weathering work out of the build. I mean plate the plastic, dunk in vinegar....voila!

Probably not doable but i thought i would ask..

where theres a will!

where theres a will!

Comment