Update,

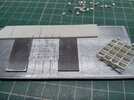

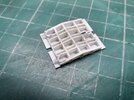

So, tried another mould after removing small parts from the master. Fairly trickled the rubber mix into all the small gaps first, and used a cocktail stick to make sure the mix was in all the corners. Then when it had set I removed the master and did a check and all the shape was there. Then I cleaned up the outside of the mould itself to get rid of any excess rubber that normally finds its way between the Lego bricks I use as the outside support. Flushed with success I then set too with the resin for the first casting, first pouring it in and making sure all the tiny gaps were filled, and with a final scrape across the top of the mould to get rid of the excess resin it was put aside to dry. So it set and when removed looked like it should, but when cleaning up I noticed one side was smaller than the other, checked the master and that was ok, so cast another nad the same result. So another casting was done and that has come out ok, and all is as it should be. But then I looked at the resin casting process and the material to be used and decided that for the small amount of resin used , the time taken and the mixing cups wasted, it would in fact be a waste of time and effort. When you take in the time to clean up the mould, mix the resin, pour it in the time you have before it sets, then the drying time and finally the clean up time, I could in fact have half of one scratch built or even built and still be left with the additional parts to be added - so that is where I am now cutting and glueing all 16..... And as it is not a race, then I can take a break and do additional work on my other build.

More later

Mike.