G

Guest

Guest

What's brass sheet like to work with Paul ? Pewter is great but so pliable and soon goes out of flat and can as you know bend easily.

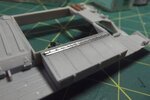

Mud guard looks good and firm looking , that why I ask.

Mud guard looks good and firm looking , that why I ask.