You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SLA /MSLA 3D printing with an Elegoo Mars Ultra - with a model making inclination

- Thread starter Gary MacKenzie

- Start date

Body and Hat printed, now to do the stand .....

Printed ( 8 hours approx @ 0.36 µm layer height ), washed in IPA ( isopropyl alcohol, a far worse smell than the resin ), then allowed to air dry overnight ( 9 hours drying approx )

Put in warm water for about 30 seconds and the supports just came away in my hand, except for a couple behind the cloak which needed a little help from small pliers, pulled, and they came off

Then cured , and now sitting in what sunlight we have today

Will be making a small led to battery cable to allow a light to be inserted inside hollow models. which will only be things like this statue, its less grief to print things solid , just a statue like this would use 3x as much resin if solid.

Tim Marlow

SMF Supporters

1/3

Really stupid question time Garry. If you printed that as a solid, then cure it, I assume only the outside where the UV light hits, gets cured? Does the inside remain uncured and therefore still soft?

For anyone interested in getting involved in this 3D printing lark, Anycubic have some really good Black Friday deals on.

For anyone interested in getting involved in this 3D printing lark, Anycubic have some really good Black Friday deals on.

1. I'm trying to keep costs down, and the only 405nm flashlight that gets good reviews that I have found is 20mm wide and as expensive as the 5 LEDs with resistors plus 5 x 9v battery press connectorsWhy not get a little UV torch for the inside of hollow models. I got mine with the UV glue that's used for fly tying.

Which is excellent stuff too

I don't know if any other wavelength light has an error in freq or spread that would also cover 405nm

It was pre-supported by Fotis Mint, but contact points were exceedingly small, will take a photo of the supports from the base later , and the bust and let you see them.That's an excellent finish you've got there,by the way. What size contact points did you use for the support?

update

approx 0.5mm

tips on the supports

I don't know when, I just followed advice from youtube peeps ( 5 mins for the bust ) and if it's still not 100% dry/cured ( i.e. slightly tacky to touch ) it gets another minuteGary,

I like that a lot! May be stupid questions, but how do you know when the print is cured? and is it possible to over cure a model?

Dave

https://forum.formlabs.com/t/is-it-possible-to-over-cure-standard-resins-or-not/11655 << one thread from a manufacturer about overcuring ......... it's a topic discussed a lot , and I am still not 100% sure of answer

Did someone mention UV torches? This is my biggest. Maybe OTT for curing prints but cures primers & fillers in seconds :smiling5:

https://www.steltools.co.uk/unilite-uv-cure-powerful-uv-curing-kit.html

I have a wash'n'cure to do outsides of prints, many use UV floodlight type systems , or nail curing lamps , I will find out more as I progress or relapse.

each slice horizontally gets cured by the system, my understanding about curing the finished model is that the outside surface will not be as cured as each of the very thin horizontal layers built up, That is horizontally printed , but most models are printed at an angle so the slice in the final model is actually approx 45 degrees thru the model.Really stupid question time Garry. If you printed that as a solid, then cure it, I assume only the outside where the UV light hits, gets cured? Does the inside remain uncured and therefore still soft?

For anyone interested in getting involved in this 3D printing lark, Elgoo have some really good Black Friday deals on.

I am printing at 36µm ( 3.6% of a millimetre or 1/26th mm approx )

Yes they do have good deals, only my printer was bought in their pre-black Friday price promise, and the difference is £15.00, so I am not going to lose sleep over it.

It was also scarcer than rocking horse poop at the time.

This is really interesting to follow, but beyond me. But your patience in getting it right is proving a real winner.

Neil Merryweather

Well-known member

1/3

I actually cure my stuff for much longer(max on my station is 30 mins!) I find it's not properly hard until at least 24 hours after.(this is the Elegoo ABS-like resin)

I haven't yet done anything that's big enough to need to be hollow.

it definitely helps to let it dry off from the IPA rinse before curing, although I don't usually leave it more than half an hour.

I haven't yet done anything that's big enough to need to be hollow.

it definitely helps to let it dry off from the IPA rinse before curing, although I don't usually leave it more than half an hour.

I must admit i am still trying to find the ''science'' for curing ( times etc )I actually cure my stuff for much longer(max on my station is 30 mins!) I find it's not properly hard until at least 24 hours after.(this is the Elegoo ABS-like resin)

I haven't yet done anything that's big enough to need to be hollow.

it definitely helps to let it dry off from the IPA rinse before curing, although I don't usually leave it more than half an hour.

I like VOGMAN's work

I am swaying to the ''no hollowing'' side of things, need to work out costs implication.

It's all down to costs long-term.This is really interesting to follow, but beyond me. But your patience in getting it right is proving a real winner.

Resin is about £20 to £30 per litre/KG

Each resin has different characteristics, so needs different settings.

I need to spend as little as possible , so , lots of testing costs resin now , but once I have the results , I can store the settings in the slicer program, and save long term.

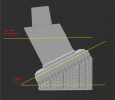

Bad day ..... first major print failure ...... the stand/base for the ''v'' character , everything else on the plate printed , so going to see about setting up supports on the ''unsupported'' version and see if it was a support failure.

Will post the successful bits later

Will post the successful bits later

Neil Merryweather

Well-known member

1/3

welcome, welcome..... :tongue-out3:Bad day ..... first major print failure ...... the stand/base for the ''v'' character , everything else on the plate printed , so going to see about setting up supports on the ''unsupported'' version and see if it was a support failure.

Will post the successful bits later

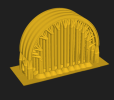

Niggle 2 : I was printing some fuel drums ,

rendered versions

All looked fine, I printed them, threw away the damaged base for the statue, and then proceeded to clean and cure.

Then I realised that the writing was mirrored ...... ok says me, one of the mirror settings in the slicer must be wrong, only the head can't work out which, so tomorrow afternoon will revolve around working out why horizontal text is ok ( the exposure tests had text the right way ), but text on a vertical surface is wrong ........ ( but was right on the cones of calibration ) ....... if everything else is symmetrical, hard to work out if anything else was mirrored ......

Also agree with many of the reviewers that the new version of the release material they use in the Mars 4 Ultra ( ACF ) leaves a weird effect on the surface of smooth surfaces, It is nowhere near as noticeable on miniatures/statues etc, where the materials hide the effect.

Looks like I will need to buy FEP/Nfep to replace the ACF if I want ultra-flat surfaces.

Will see if a coat of paint can hide the effect.

rendered versions

All looked fine, I printed them, threw away the damaged base for the statue, and then proceeded to clean and cure.

Then I realised that the writing was mirrored ...... ok says me, one of the mirror settings in the slicer must be wrong, only the head can't work out which, so tomorrow afternoon will revolve around working out why horizontal text is ok ( the exposure tests had text the right way ), but text on a vertical surface is wrong ........ ( but was right on the cones of calibration ) ....... if everything else is symmetrical, hard to work out if anything else was mirrored ......

Also agree with many of the reviewers that the new version of the release material they use in the Mars 4 Ultra ( ACF ) leaves a weird effect on the surface of smooth surfaces, It is nowhere near as noticeable on miniatures/statues etc, where the materials hide the effect.

Looks like I will need to buy FEP/Nfep to replace the ACF if I want ultra-flat surfaces.

Will see if a coat of paint can hide the effect.

Attachments

The no1 rule : everything at approximately 45 degrees , very quickly breaks down.

flat surfaces, especially large flat surfaces are a nightmare at an angle.

at least the flat stuff I am trying isn't anything essential, but I will have to reprint a couple of things .... having said that, the resin is a lot more robust than the styrene sheet when I tried the same idea.

flat surfaces, especially large flat surfaces are a nightmare at an angle.

at least the flat stuff I am trying isn't anything essential, but I will have to reprint a couple of things .... having said that, the resin is a lot more robust than the styrene sheet when I tried the same idea.

G

Guest

Guest

Interesting to try to read and understand Gary, you must be thrilled at the progress you've made since the start of this . I'm like Paul it's all beyond me

one step forward, and no idea how far back again some times.Interesting to try to read and understand Gary, you must be thrilled at the progress you've made since the start of this . I'm like Paul it's all beyond me

it's like cutting pieces of wood to make an insert for something where you have to take into consideration the thickness of the materials along with the dimensions it needs to fit , to get all the pieces the correct size, long time since I did all the calcs at once and not by cutting inserting and then working out dimensions of next piece, where you can see a mistake straight away,

At least its keeping the brain busy .....

Legal Notice

scalemodelling.co.uk is a privately operated online discussion forum. All content posted by members reflects their own views and opinions and does not necessarily represent those of the forum owners or administrators. While reasonable efforts are made to moderate content, no responsibility is accepted for user-generated material. By using this site, you agree to comply with UK law and the forum rules.