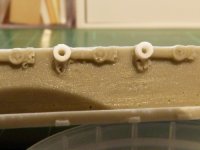

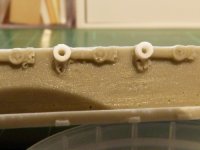

A little bit more progress. I've sorted the wheels as best as I can. The fixing of the road wheels looked very iffy so I inserted short lengths of stiff wire.

I cut off the fixing "blobs" and added small pieces of styrene tube to the body and also drilled through the tube into the body to accept the wires.

The bubbles and bad casting will be covered by the road wheels so I'm not too bothered about that.

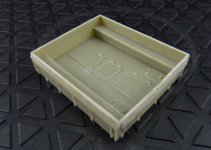

Next I needed to look at the tracks. The kit provides a few straight resin lengths. Top and bottom, across the 5 road wheels, is a nice straight run. It's the bending round the drive and idler wheels that presents problems.

I made a couple of simple jigs and heated a track length with a hair dryer and bent the track around the wheels. I glued the track to the wheels , just at the end of the curve, with 2 part epoxy. I figured that CA would not be secure enough.

So I ended up with these.

The plan is to fit the wheels with their lengths of track in place and cut the track at the top and bottom of the adjacent road wheel and glue the cut ends to the road wheel, again with epoxy. The front to back gap will be a cut to size straight length.

So we will see haw the idea works. I'll do a bit of painting first.

I'm finding it quite a challenge but strangely satisfying.

. Russians did seem to like ugly vehicles (nothing to do with your modelling though mate). But she ain't the prettiest

. Russians did seem to like ugly vehicles (nothing to do with your modelling though mate). But she ain't the prettiest  . Never built a Russian vehicle Jim, will this be in that Green colour that seems to cause some debate in the matching ?

. Never built a Russian vehicle Jim, will this be in that Green colour that seems to cause some debate in the matching ?