Neil Merryweather

Well-known member

1/3

As promised I have been conducting tests on how to create the hull with all its rivets (1,064 - ish)

My main concern is the huge number of rivets that absolutely MUST be placed in straight lines and evenly spaced. I don’t have the skill or the patience to do that by hand, so I’ve got to find some way of reliably controlling the placement of them. Also, I want to create the effect of slightly battered metal, so my first instinct was to use thin metal like the copper sheet I used in my Higgins boat build. So, how to create the rivets? I do have a rivet punch, but over a thousand? I don’t think so! Pins, maybe?

I don’t have any with a small enough head(0.65mm diameter in my digital model), and I don’t even know if they exist, but let’s just prove the concept for starters. Now I need to create a straight line of holes at precise intervals, and I remembered my device for planting rye grass in my Fusiliers diorama- the dressmaker’s tracing wheel

I don’t really like the way the pins have dimpled the metal, it’s not appropriate for warship steel plate, but let’s carry on and see what it’s like painted.

I actually like the effect of imprinting from the reverse - the indents are a better size, but they are pierced all the way through. I ran some CA in from behind to hopefully plug the holes so we’ll see how that looks when it’s painted.

Hmm, not bad. The holes are still showing but I quite like the effect. Maybe there’s a way of getting around that. And the dimpling of the pins is not so noticeable.

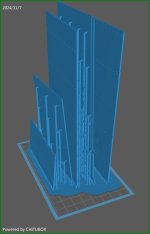

Next I tried 3D printing the rivets, ready-spaced in a line. I placed them on stalks in a line of 16 on a bar. Here’s the digital model, it’s a lot clearer than I can photograph.

It certainly beats punching over 1000 by hand, but it was tricky to glue accurately and without leaving glue marks (TET). But it might be worth developing further.

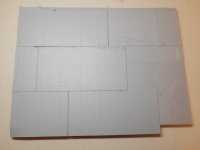

I made quite a large sample panel (using 0.5mm PETG sheet because that’s all I have that’s big enough) because I wanted to experiment with ways of representing the welded seams.

I used two thicknesses of thin solder wire and thin plastic rod because the horizontal welds are chunkier than the vertical ones. It seemed like a good idea to try and reproduce the actual process, so I melted them with a soldering iron and laid them into scribed panel lines. I had real trouble gluing the solder until I degreased it - MUST remember that.....

The whole point of this is to test the techniques so I thought I would try drilling multiple holes in straight lines to see exactly how tricky it is. I used the flexible drive on my mini drill(not a Dremel, which doesn’t go slow enough) and amazingly it didn’t melt the plastic too much, I guess because it’s so thin. And it wasn’t as difficult as I expected either. I added a few dents too with various blunt implements.

So how does this look painted?

Kind of ok , but I am not happy with the glued rivets and the weld seams don’t really work.

And I must remember to dust it before I spray it for real....

So the next logical step is to see if I can 3D print the entire panel, rivets and all....

Stay tuned folks....

Cheers

Neil

My main concern is the huge number of rivets that absolutely MUST be placed in straight lines and evenly spaced. I don’t have the skill or the patience to do that by hand, so I’ve got to find some way of reliably controlling the placement of them. Also, I want to create the effect of slightly battered metal, so my first instinct was to use thin metal like the copper sheet I used in my Higgins boat build. So, how to create the rivets? I do have a rivet punch, but over a thousand? I don’t think so! Pins, maybe?

I don’t have any with a small enough head(0.65mm diameter in my digital model), and I don’t even know if they exist, but let’s just prove the concept for starters. Now I need to create a straight line of holes at precise intervals, and I remembered my device for planting rye grass in my Fusiliers diorama- the dressmaker’s tracing wheel

I don’t really like the way the pins have dimpled the metal, it’s not appropriate for warship steel plate, but let’s carry on and see what it’s like painted.

I actually like the effect of imprinting from the reverse - the indents are a better size, but they are pierced all the way through. I ran some CA in from behind to hopefully plug the holes so we’ll see how that looks when it’s painted.

Hmm, not bad. The holes are still showing but I quite like the effect. Maybe there’s a way of getting around that. And the dimpling of the pins is not so noticeable.

Next I tried 3D printing the rivets, ready-spaced in a line. I placed them on stalks in a line of 16 on a bar. Here’s the digital model, it’s a lot clearer than I can photograph.

It certainly beats punching over 1000 by hand, but it was tricky to glue accurately and without leaving glue marks (TET). But it might be worth developing further.

I made quite a large sample panel (using 0.5mm PETG sheet because that’s all I have that’s big enough) because I wanted to experiment with ways of representing the welded seams.

I used two thicknesses of thin solder wire and thin plastic rod because the horizontal welds are chunkier than the vertical ones. It seemed like a good idea to try and reproduce the actual process, so I melted them with a soldering iron and laid them into scribed panel lines. I had real trouble gluing the solder until I degreased it - MUST remember that.....

The whole point of this is to test the techniques so I thought I would try drilling multiple holes in straight lines to see exactly how tricky it is. I used the flexible drive on my mini drill(not a Dremel, which doesn’t go slow enough) and amazingly it didn’t melt the plastic too much, I guess because it’s so thin. And it wasn’t as difficult as I expected either. I added a few dents too with various blunt implements.

So how does this look painted?

Kind of ok , but I am not happy with the glued rivets and the weld seams don’t really work.

And I must remember to dust it before I spray it for real....

So the next logical step is to see if I can 3D print the entire panel, rivets and all....

Stay tuned folks....

Cheers

Neil