You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone know?

- Thread starter Bri62

- Start date

Tim Marlow

SMF Supporters

1/3

https://exito.site/en_GB/p/DSPIAE-DB-01-2.0-Modelling-drill-bit-2.0mm/60781

3.175mm according to this place Brian. I think that’s 1/8 inch in old money….

3.175mm according to this place Brian. I think that’s 1/8 inch in old money….

I have a set and they are indeed 3.2mm / 1/8"

They don't fit in some of their own holders that are 3.0mm :tears-of-joy:so check that as well.

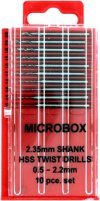

To be honest I don't rate them, I've broken half of mine after only a couple of uses, whereas the modelcraft / microbox set I have is still going strong after a few years. Never broken one, but lost several lol

They don't fit in some of their own holders that are 3.0mm :tears-of-joy:so check that as well.

To be honest I don't rate them, I've broken half of mine after only a couple of uses, whereas the modelcraft / microbox set I have is still going strong after a few years. Never broken one, but lost several lol

Tim Marlow

SMF Supporters

1/3

To my mind, a 2mm HSS drill should be tough enough for any modelling application. Why do you need the shank on it?

I don't need it but the 2.3mm shank fits the collet in my tamiya electric drill nice and having them all the same is good no matter if it's a 0.4 or 2.3 drillo my mind, a 2mm HSS drill should be tough enough for any modelling application. Why do you need the shank on it?

Tim Marlow

SMF Supporters

1/3

Ah, get it now, you have a collet chuck, not a four jaw. Would another approach be to look for a different collet set for the chuck so standard drills would fit?I don't need it but the 2.3mm shank fits the collet in my tamiya electric drill nice and having them all the same is good no matter if it's a 0.4 or 2.3 drill

Tim Marlow

SMF Supporters

1/3

Not making it easy for you are they  . Looks like they‘ll do the job though :thumb2:

. Looks like they‘ll do the job though :thumb2:

Tim Marlow

SMF Supporters

1/3

You can resharpen HSS quite easily. Used to be able to buy a device to sharpen mini drills, but I can’t remember what it was called……

Drill sharpening tool ?.... (sorry mate, couldn't resist...lol)You can resharpen HSS quite easily. Used to be able to buy a device to sharpen mini drills, but I can’t remember what it was called……

G

Guest

Guest

Micrbox every time, some of the other knockoff offerings are s............ and made of the same stuff. Like you I can go through the cheapies like water...I have a set and they are indeed 3.2mm / 1/8"

They don't fit in some of their own holders that are 3.0mm :tears-of-joy:so check that as well.

To be honest I don't rate them, I've broken half of mine after only a couple of uses, whereas the modelcraft / microbox set I have is still going strong after a few years. Never broken one, but lost several lol

Tim Marlow

SMF Supporters

1/3

It’s called a wishbone drill sharpener Brian, designed for micro drills.

Very droll Chris…….

Drill sharpening tool ?.... (sorry mate, couldn't resist...lol)

Very droll Chris…….

Tim Marlow

SMF Supporters

1/3

Must admit I just buy replacements as job lots ten at a time and use the micro box to hold them. Don’t break many, even the very small ones , but I don’t use them powered. I just use them manually powered in a hand Chuck. I think powered mini drills are designed to break drills and sell more drills :upside: In sheet stock I sometimes just drill a pilot hole and open it to size using a five sided tapered broach.Micrbox every time, some of the other knockoff offerings are s............ and made of the same stuff. Like you I can go through the cheapies like water...

Dspiae drill bits are far to brittle and snap if you look at them weird.

I have had some drill bits several years and not broken them, those from Dspiae I went through a box in an afternoon. Three broke finding centre!

I have had some drill bits several years and not broken them, those from Dspiae I went through a box in an afternoon. Three broke finding centre!

WELL when i first started work in crane fruehuaf at the tender age of 16 it was my first job of sharpening all the thounds of domer drills on a machine an then after that i just then an now just sharpen them drills by hand on a bench mounted grindein wheel an its just a matter of makin sure i dont back them off wrong so the cuttin edges are backwards as it easy done if not concentratein

chrisb

chrisb

- Joined

- Mar 4, 2004

- Messages

- 4,739

- Website

- www.scalemodelshop.co.uk

- Location

- Halifax

- How do you identify?

- Apache Attack Helicopter

- Pronouns

- Whatever / Works

1/3

I replied to your email, didn’t you get it? They are 3.175mm, as people have said, tungsten is much softer than steel and they do break easyHi what size the shank is on these drill bits

Tungsten Steel Drill Bit DSPIAE DB-01-20

No john thought you must be busy but all good :smiling3:I replied to your email, didn’t you get it?

Just found it in my spam folder

G

Guest

Guest

I agree, I went daft at the comps and bought myself an archemedes drill not realising you need two hands to use it, and there go all the drills....Must admit I just buy replacements as job lots ten at a time and use the micro box to hold them. Don’t break many, even the very small ones , but I don’t use them powered. I just use them manually powered in a hand Chuck. I think powered mini drills are designed to break drills and sell more drills :upside: In sheet stock I sometimes just drill a pilot hole and open it to size using a five sided tapered broach.

Legal Notice

scalemodelling.co.uk is a privately operated online discussion forum. All content posted by members reflects their own views and opinions and does not necessarily represent those of the forum owners or administrators. While reasonable efforts are made to moderate content, no responsibility is accepted for user-generated material. By using this site, you agree to comply with UK law and the forum rules.