Hi all

Once again I'm truly blown away with such great support.

To answer Tim's very valid point about calking the deck planks. The instructions do say to show this. Their method is to run a black felt tip along the plank edges before fitting. That doesn't work because the wood is porous and the black spreads/soaks into the wood and the calk line becomes blurry. As each plank is different the unwanted effect was worse on some than on others. I tried various pens with similar disappointing results. I tried spirit based pens but they were worse. Enamel paint worked OK but that tended to seal the wood and so the PVA wood glue didn't stick well and the planks didn't lay flat to each other. To be honest I gave up and thought the buggers in the upper gun deck would just have to put up with a bit of wet!! :smiling5:

I've had a pretty good couple of days on this.

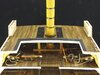

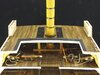

First job was to complete the quarter deck planking around the deck openings. Those openings were just frames but on the actual ship they have a grid covering them. I found some suitable mesh in the spares box. I then planked the small bulwark and framed the cockpit. I also fitted the mast collar.

Rails fit around the cockpit.

As you can see the instructions want 4mm lengths from 3mm square wood. Oh yer!!? The wood just splits along the grain so I have used 3mm square styrene tube. It will all be painted black anyway

Thanks again guys :thumb2:

Jim

Once again I'm truly blown away with such great support.

To answer Tim's very valid point about calking the deck planks. The instructions do say to show this. Their method is to run a black felt tip along the plank edges before fitting. That doesn't work because the wood is porous and the black spreads/soaks into the wood and the calk line becomes blurry. As each plank is different the unwanted effect was worse on some than on others. I tried various pens with similar disappointing results. I tried spirit based pens but they were worse. Enamel paint worked OK but that tended to seal the wood and so the PVA wood glue didn't stick well and the planks didn't lay flat to each other. To be honest I gave up and thought the buggers in the upper gun deck would just have to put up with a bit of wet!! :smiling5:

I've had a pretty good couple of days on this.

First job was to complete the quarter deck planking around the deck openings. Those openings were just frames but on the actual ship they have a grid covering them. I found some suitable mesh in the spares box. I then planked the small bulwark and framed the cockpit. I also fitted the mast collar.

Rails fit around the cockpit.

As you can see the instructions want 4mm lengths from 3mm square wood. Oh yer!!? The wood just splits along the grain so I have used 3mm square styrene tube. It will all be painted black anyway

Thanks again guys :thumb2:

Jim