1/3

Your Welcome Chris be dropping in to check the progress now and then

Chris,

the joys of short run models! I leave the glue well alone until I've dry fitted and adjusted things for 'best' fit. It can help to add plastic card strips to aid location in fuselages. I go back to the old method ( from making vacforms ) by having a sheet of wet & dry on a thick piece of flat board, and sanding component faces square ( use wet, less dust! ) - I even do this on mainstream models occasionally, if needed, removing location tabs/pins in the process.

Dave

Good tip! Won’t be the last time I need this, so thanks!Chris,

with short run kits, and butt joined wings, I drill holes in the wing roots & fuselage <1mm dia, and use copper wire as the strength member - copper, so you can adjust the dihedral, etc before committing to cement!

Dave

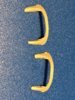

Two of the same rather than a left & right pair?Can anyone tell me what is wrong with these elevators...

scalemodelling.co.uk is a privately operated online discussion forum. All content posted by members reflects their own views and opinions and does not necessarily represent those of the forum owners or administrators. While reasonable efforts are made to moderate content, no responsibility is accepted for user-generated material. By using this site, you agree to comply with UK law and the forum rules.