The gold filament was a disappointment! The first print got halfway through, then came off the build plate - no idea why, but it wasted quite a bit of filament - I'd only bought 5m.. The second king stuck OK, but the gold looks more beige and the layering is terrible, overall a failure........

Obviously the filament settings need tweaking, but I don't have enough filament for another try - I'll forget about this!

Just normal filament, then primed with the pawn

Much better - hardly any layering visible

I saw this on Thingiverse, by user 'deepstatic', and couldn't resist it

I had to use supports under the chin, but they came away without a problem, without even th use of a knife.

There's loads of elves, goblins & space aliens available, but the ones I'm looking for, Medieval Knights, I haven't found any suitable for FDM printing - they may be out there, but not filed under a reasonable title! Chess pieces are small enough to print reasonably quickly, and are varied in their details - although printing out 32 pieces would take quite a bit of time!

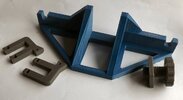

I've got a few mods to the printer to fit........................

The blue bit is a brace for the front plate & the grey bits are for a Y-axis belt tensioner - the existing arrangement isn't very good! I do have a spare set of belts, just in case something goes wrong

Dave

Obviously the filament settings need tweaking, but I don't have enough filament for another try - I'll forget about this!

Just normal filament, then primed with the pawn

Much better - hardly any layering visible

I saw this on Thingiverse, by user 'deepstatic', and couldn't resist it

I had to use supports under the chin, but they came away without a problem, without even th use of a knife.

There's loads of elves, goblins & space aliens available, but the ones I'm looking for, Medieval Knights, I haven't found any suitable for FDM printing - they may be out there, but not filed under a reasonable title! Chess pieces are small enough to print reasonably quickly, and are varied in their details - although printing out 32 pieces would take quite a bit of time!

I've got a few mods to the printer to fit........................

The blue bit is a brace for the front plate & the grey bits are for a Y-axis belt tensioner - the existing arrangement isn't very good! I do have a spare set of belts, just in case something goes wrong

Dave