Hi Everyone

Si - Thanks for the offer mate:thumb2: You know me, I like to add lots of detail:smiling3:

Richard - I am thinking of doing all the wiring on the under carriage as well but we will see how I feel when I get to it

JR - Sadly not mate as I am a southern softy. However I am certifiably madder than Mad Jack McMad, the winner of last year’s Mr Madman competition:smiling5:

Well today has been a rewarding day at the bench. The task was to scratch build the sledge for the flak unit to go on. I have unashamedly copied Ron Lebert's wonderful blog that he did in 2010 on the site with no name about how to build the sledge. Although not as good as his, and despite the disaster at the end, it hasnt turned out to bad.

So firstly we need a base.

View attachment 301169

Following Ron's hand made scale drawing of the base, I cut a piece to the right size and added a central line to work off.

View attachment 301170

I then drew on the shape that needs to be cut away. I dont have the correct tools to do this exactly so I used free hand and then sanded it into shape.

View attachment 301171

I then checked the Flak base would fit in position okay:thumb2:

View attachment 301172

Next I made the stops for the three feet on the Flak base. I dont have a drill bit this size so again this was done free hand and they came out "okay"

View attachment 301173View attachment 301174View attachment 301176

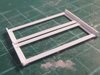

Next I had to build a simple frame underneath. I did not have the correct size struts so I doubled up the ones I had and glued them together

View attachment 301177

These were then cut to size according to Ron's instructions, sanded and glued into place. I also added a couple of supporting struts

View attachment 301179

Next the rollers were made from these parts. One day I will learn how to cut a piece of tubing straight:smiling2:

View attachment 301180

These were then put at the front and end of the sledge. There should be one in the middle but as this will not be seen I didnt bother

View attachment 301181

Next I attempted the criss cross support at the top. My first effort on the R/H side was to thick. So I cut a smaller strip and this looked far better

View attachment 301182

Final detailing was added with copper handles, bolt heads and rivets

View attachment 301183View attachment 301184

I then put it onto the truck and DISASTER! It was too long!!. Ron had designed his sledge to go up against the back board of the truck. I actually needed mine to be shorter and supported by a plank of wood bolted onto the floor.DOH! So I had to go all the way back to the beginning and build another one. Yeah - that aint happening:thinking:. So I cut 7mm off the end and redid the handles which I was happy to do as I was not happy with the first ones. The cross members were left as is so it's a little out of proportion. However if we dont tell any one we should get away with it:tongue-out3:

View attachment 301185

So as you can see it fits as it should do and the support plank will fit okay now and it still leaves the damaged plank ends showing:thumb2:

View attachment 301186View attachment 301187

The support planks around the outside will be tomorrows challenge

Thanks for watching.

Steve