You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Neil's 1-35 Liberty Ship Diorama

- Thread starter Neil Merryweather

- Start date

Neil Merryweather

Well-known member

1/3

VERYwell done Neil just looked through your thread an am most impressed keep it comin

chrisb

Very glad to have an expert aboard, Chris!

Very glad to have an expert aboard, Chris!

well Neil i dont know about an exspert but i know a little an what you are doin looks good an i will follow on

chrisb

Neil Merryweather

Well-known member

1/3

Let’s leave rivet counting for now and look at the re-alignment of the whole diorama...

Thanks to a suggestion on another forum I have re-oriented the base slightly to offset it from the totally orthogonal , as much as I can without affecting the walls I printed earlier.

I used the CAD model to plot the difference between the old position and the new, and I set to with the scalpel

I will need to add a small triangle a the left hand side (top), which gives me a horrible polygonal block to work with.

I didn’t mention it earlier but I have made my life even more difficult by angling the back surface backwards so that I can eventually tilt the whole thing to the front a bit.

So now the only right-angles are the back two corners and the vertical plane-

Thank God for CAD!

I had by this time detailed the two feature walls

Although I managed not to change the detailed walls I did have to change the blank back and side walls, and thanks to CAD I was able to 3D print some braces to the correct angles(they are the blue bits)

That’s all for now folks

Thanks for watching

Neil

Thanks to a suggestion on another forum I have re-oriented the base slightly to offset it from the totally orthogonal , as much as I can without affecting the walls I printed earlier.

I used the CAD model to plot the difference between the old position and the new, and I set to with the scalpel

I will need to add a small triangle a the left hand side (top), which gives me a horrible polygonal block to work with.

I didn’t mention it earlier but I have made my life even more difficult by angling the back surface backwards so that I can eventually tilt the whole thing to the front a bit.

So now the only right-angles are the back two corners and the vertical plane-

Thank God for CAD!

I had by this time detailed the two feature walls

Although I managed not to change the detailed walls I did have to change the blank back and side walls, and thanks to CAD I was able to 3D print some braces to the correct angles(they are the blue bits)

That’s all for now folks

Thanks for watching

Neil

Neil, cracking work mate.

Looking good to date!

Steve

Steve

Fantastic Neil, I step out for a while and you come up with building a Dio that's going to be great. It may have been hatching for ten years but seeing it being done with 3D printing thrown in is something else. Worth the wait.

Pour it on...eh I mean build it up. Apologiess for coming in so late.

Cheers,

Wabble

Pour it on...eh I mean build it up. Apologiess for coming in so late.

Cheers,

Wabble

Neil Merryweather

Well-known member

1/3

I’m going away for a few days so I want to post something so you don’t forget me...

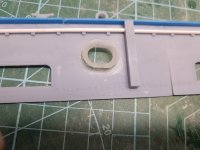

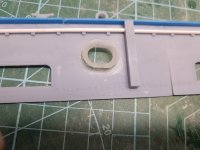

I’m still mulling over the various options for rivets but in the meantime I have created the upstand walls of this deck, which I am calling the Main Deck. There is actually a break between the main hull sides and these - they are not just a continuation of the hull.

That’s not me ,by the way.

As with the hull sides I had originally expected to make them out of plastic sheet, but these files were created at the same time as the files for the hull side experiment, and happily I DID manage to 3D print these smaller pieces of flat section in resin successfully, complete with their rivets. The handrails were not so successful as they warped like crazy, so rather than persevere with the resin I did them on the FDM printer ,which is why they are blue.

The handrails did have their rivets included but they looked awful so as there was only about 100 I decided to do sand them off and do them by hand.

You may wonder why I didn’t include every bit of detail and print each piece complete - well the answer is it‘s a question of minimising the amount of supports to remove; it's the equivalent in aggro of removing mould lines and sprue gates on an injection moulded model. So as I am master of my own destiny this is the way I do it - in this case more bits mean less work - call me ICM if you like!

There are still vertical fins to add to the inside, they are printed but they will have to wait

That's it for now, thanks for watching and see you next week!

Cheers

Neil

I’m still mulling over the various options for rivets but in the meantime I have created the upstand walls of this deck, which I am calling the Main Deck. There is actually a break between the main hull sides and these - they are not just a continuation of the hull.

That’s not me ,by the way.

As with the hull sides I had originally expected to make them out of plastic sheet, but these files were created at the same time as the files for the hull side experiment, and happily I DID manage to 3D print these smaller pieces of flat section in resin successfully, complete with their rivets. The handrails were not so successful as they warped like crazy, so rather than persevere with the resin I did them on the FDM printer ,which is why they are blue.

The handrails did have their rivets included but they looked awful so as there was only about 100 I decided to do sand them off and do them by hand.

You may wonder why I didn’t include every bit of detail and print each piece complete - well the answer is it‘s a question of minimising the amount of supports to remove; it's the equivalent in aggro of removing mould lines and sprue gates on an injection moulded model. So as I am master of my own destiny this is the way I do it - in this case more bits mean less work - call me ICM if you like!

There are still vertical fins to add to the inside, they are printed but they will have to wait

That's it for now, thanks for watching and see you next week!

Cheers

Neil

Excellent work Neil. Its fascinating watching the build process from the start.

Neil great work keep it coming mate.

Neil Merryweather

Well-known member

1/3

Right, Christmas is over and I’ve done all I am obliged to do for SWMBO and others (well,mostly...) the family have dispersed around the country and now I can knuckle down and report on the progress of SS Jeremiah O’Brien.

Some of this work was done a while ago but I just didn’t have time to write it up. Anyway,I finally decided what to use for rivets for the vertical ribs, and it is these bad boys.

I have chosen pins because I can just poke them into the plastic and the foamboard behind without any unsightly glue marks. The heads are 0.99mm diameter which by my rudimentary maths makes them the scale equivalent of an inch and a half, which I think is about right ,looking at the pics I have. They weren't cheap but I think they are the least painful method.

In the absence of any more considered research I have decided that they were probably spaced 6 inches apart, and that the ribs would probably be 3 feet apart,which would be 26mm at 1-35 scale.

So if I use strips of 25mm masking tape as my spacer that will be close enough for me

Continuing my laissez-faire approach to accuracy I marked the vertical spacing at quarter-inch intervals, which at scale is 6mm-ish. By my previous logic at 6 inches or 150mm it ought to be 4.2mm, but I didn’t care.

I then spent 4 hours drilling 1034 holes (OMG that makes me literally a rivet-counter!) with a 0.35mm drill bit (or five...). During this operation my minidrill (not a Dremel) decided to malfunction, requiring dismantling and re-soldering a loose connection to the switch. I have an alternative but the chuck doesn’t accept a 0.35mm drill!!

So that’s where the hull is at the moment- you will see that I have added a couple of dents, but not to the extreme state of the present-day ship.

There's a bit more done but I thought I would post this for now.

Some of this work was done a while ago but I just didn’t have time to write it up. Anyway,I finally decided what to use for rivets for the vertical ribs, and it is these bad boys.

I have chosen pins because I can just poke them into the plastic and the foamboard behind without any unsightly glue marks. The heads are 0.99mm diameter which by my rudimentary maths makes them the scale equivalent of an inch and a half, which I think is about right ,looking at the pics I have. They weren't cheap but I think they are the least painful method.

In the absence of any more considered research I have decided that they were probably spaced 6 inches apart, and that the ribs would probably be 3 feet apart,which would be 26mm at 1-35 scale.

So if I use strips of 25mm masking tape as my spacer that will be close enough for me

Continuing my laissez-faire approach to accuracy I marked the vertical spacing at quarter-inch intervals, which at scale is 6mm-ish. By my previous logic at 6 inches or 150mm it ought to be 4.2mm, but I didn’t care.

I then spent 4 hours drilling 1034 holes (OMG that makes me literally a rivet-counter!) with a 0.35mm drill bit (or five...). During this operation my minidrill (not a Dremel) decided to malfunction, requiring dismantling and re-soldering a loose connection to the switch. I have an alternative but the chuck doesn’t accept a 0.35mm drill!!

So that’s where the hull is at the moment- you will see that I have added a couple of dents, but not to the extreme state of the present-day ship.

There's a bit more done but I thought I would post this for now.

Been impressed all the way through Neil. even more so now!

Steve

Steve

Legal Notice

scalemodelling.co.uk is a privately operated online discussion forum. All content posted by members reflects their own views and opinions and does not necessarily represent those of the forum owners or administrators. While reasonable efforts are made to moderate content, no responsibility is accepted for user-generated material. By using this site, you agree to comply with UK law and the forum rules.