Ok as promised, heres the kit all i have done so far is cut out thechrome wheel parts and stripped them down.

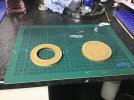

also i made this jig 2 round 6mm hardboard circles (just easier to cut) now i plan to bond one on to the other and this should hold the wheel parts in place while i re spoke them thats the plan anyway idea is it will keep it square while the glue sets

simon

also i made this jig 2 round 6mm hardboard circles (just easier to cut) now i plan to bond one on to the other and this should hold the wheel parts in place while i re spoke them thats the plan anyway idea is it will keep it square while the glue sets

simon