Neil Merryweather

Well-known member

1/3

I first posted this in What's On The Bench, but I think it might expand a bit, so here's a full thread.

I got a bit 'Fusiliered Out' so I started building this digitally for a diorama I'm planning, using up my stash of Airfix Multipose US Marines.

Of course nobody does any accessories in 1-32 scale now ,so I measured a 1-35 offering by Dragon, and scaled up to full size, then I re-scaled to 1-32.

Here's a WIP screen shot -the different colours are all the separate elements which are individually editable until I combine them together and 'fix' them once I am happy

It took me a few days but here's the final piece

The carrying frame is very thin so I have made 3 versions in different thicknesses as a safety net.

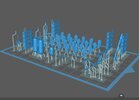

Here's a pic showing how I've separated the various components for printing

There should be a canvas panel suspended between the verticals of the carrying frame, but I will fabricate that, along with the flexible hose.

So fingers crossed I will be printing this tonight

FYI it's 22mm tall

I got a bit 'Fusiliered Out' so I started building this digitally for a diorama I'm planning, using up my stash of Airfix Multipose US Marines.

Of course nobody does any accessories in 1-32 scale now ,so I measured a 1-35 offering by Dragon, and scaled up to full size, then I re-scaled to 1-32.

Here's a WIP screen shot -the different colours are all the separate elements which are individually editable until I combine them together and 'fix' them once I am happy

It took me a few days but here's the final piece

The carrying frame is very thin so I have made 3 versions in different thicknesses as a safety net.

Here's a pic showing how I've separated the various components for printing

There should be a canvas panel suspended between the verticals of the carrying frame, but I will fabricate that, along with the flexible hose.

So fingers crossed I will be printing this tonight

FYI it's 22mm tall