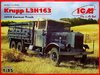

After the Revell/ICM 1/48 Mig-25, I'm going to build the 1/35 Krupp 6 X 4 Heavy Truck, also from the ICM stableView attachment 314893

The box is full of plastic - the construction is pretty complex, the chassis is flat pack - no slide moulding!

The instructions are busy...................... 2 finish variants - both grey early warView attachment 314890View attachment 314895View attachment 314894

Some of the parts are fragile - I can see problems getting this off the sprues in one piece! - Rear axles brake linkages...........View attachment 314891

Some neatly moulded parts - springs, & fan for the complete engineView attachment 314897View attachment 314892

Radiator...............View attachment 314896

The wheels and tyres are one piece - no vinyl here! ( good!!! )View attachment 314898

Looks like it will be a pretty fiddly build, I've made a few ICM trucks, and as long as the chassis is built square, then all should be well

Construction will start shortly!

Dave

The box is full of plastic - the construction is pretty complex, the chassis is flat pack - no slide moulding!

The instructions are busy...................... 2 finish variants - both grey early warView attachment 314890View attachment 314895View attachment 314894

Some of the parts are fragile - I can see problems getting this off the sprues in one piece! - Rear axles brake linkages...........View attachment 314891

Some neatly moulded parts - springs, & fan for the complete engineView attachment 314897View attachment 314892

Radiator...............View attachment 314896

The wheels and tyres are one piece - no vinyl here! ( good!!! )View attachment 314898

Looks like it will be a pretty fiddly build, I've made a few ICM trucks, and as long as the chassis is built square, then all should be well

Construction will start shortly!

Dave