Assembling the Sunlu T3 printer took about half an hour - 10 bolts, four of which were for the spool holder!

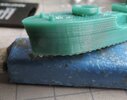

It has a bed size comparable to the Anet, the frame is aluminium extrusions & the body of sheet steel. It has a Bowden style feed, with an all-metal geared extruder. The power supply gives 24V, and heats up the bed & nozzle very quickly. It took me a while to work out the sequence of levelling the bed, the instructions seem to be counter intuitive! It's now set, and before each print it does a 15 point check of the bed height & compenates. First print I did was rubbish - the printer clattered and groaned, but was very fast. I found that I had not unchecked the 'fast print' mode in the printer menu, and it was printing at 3 or 4 times the normal speed! Now, it is printing - it's very quiet, most noise is from the cooling fans! You are allegedly able to print at 200mm/sec, but the quality would be rubbish. I've been printing at 80mm/sec - twice the speed of the Anet. I still need to tweak the settings to improve the finishes & reduce stringing, but that shouldn't take too long. I'll put up some pictures tomorrow.

Dave

It has a bed size comparable to the Anet, the frame is aluminium extrusions & the body of sheet steel. It has a Bowden style feed, with an all-metal geared extruder. The power supply gives 24V, and heats up the bed & nozzle very quickly. It took me a while to work out the sequence of levelling the bed, the instructions seem to be counter intuitive! It's now set, and before each print it does a 15 point check of the bed height & compenates. First print I did was rubbish - the printer clattered and groaned, but was very fast. I found that I had not unchecked the 'fast print' mode in the printer menu, and it was printing at 3 or 4 times the normal speed! Now, it is printing - it's very quiet, most noise is from the cooling fans! You are allegedly able to print at 200mm/sec, but the quality would be rubbish. I've been printing at 80mm/sec - twice the speed of the Anet. I still need to tweak the settings to improve the finishes & reduce stringing, but that shouldn't take too long. I'll put up some pictures tomorrow.

Dave