You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I.D.F M113 Fitter

- Thread starter Isitme

- Start date

Update.

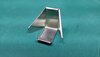

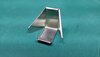

Rather than add the light guards which would get knocked off or damaged I decided to go ahead and build the side lockers and as the front left is the chosen side I decided to make it out of metal sheet. So all measured out and bent to shape, then remembered the old old proverb, measure twice, cut once. It was supposed to be 9mm and not 10mm wide :sad: Dummy.....

Bending taking shape...

More bending - nearly there....

There we are - now I will do the correct one..... Now which wall have I not banged my head against.....

Mike.

Rather than add the light guards which would get knocked off or damaged I decided to go ahead and build the side lockers and as the front left is the chosen side I decided to make it out of metal sheet. So all measured out and bent to shape, then remembered the old old proverb, measure twice, cut once. It was supposed to be 9mm and not 10mm wide :sad: Dummy.....

Bending taking shape...

More bending - nearly there....

There we are - now I will do the correct one..... Now which wall have I not banged my head against.....

Mike.

G

Guest

Guest

Mike, so you're saying that was just a practice piece. It's rather good, hope the correct one is as good!:smiling3:

No, this was going to be the original except it was 1mm too wide. Answer your phone....Mike, so you're saying that was just a practice piece. It's rather good, hope the correct one is as good!:smiling3:

Mike.

Hi Mike

May be slightly the wrong size but looks great as John says. Rather refreshing to know that even modellers of your calibre cock up like the rest of us :tongue-out3:

Jim

May be slightly the wrong size but looks great as John says. Rather refreshing to know that even modellers of your calibre cock up like the rest of us :tongue-out3:

Jim

G

Guest

Guest

Give me time to find it and answer ! :smiling3:No, this was going to be the original except it was 1mm too wide. Answer your phone....

Mike.

1/3

More exceptional work on show Mike. Just had a catch up and am suitably impressed with the jig idea from a couple of pages back. Looks like it will be fun painting this lot though.....lots to knock off!

I will not answer that as children (those under 60) can read this....Hi Mike

May be slightly the wrong size but looks great as John says. Rather refreshing to know that even modellers of your calibre cock up like the rest of us :tongue-out3:

Jim

I like your confidence in my ability to knock things off while painting - you have not seen my painting yet :flushed:....More exceptional work on show Mike. Just had a catch up and am suitably impressed with the jig idea from a couple of pages back. Looks like it will be fun painting this lot though.....lots to knock off!

When you find it call me, if you use it and the tv keeps changing channels then pick up the remote, that is your phone, or has the man come and taken back the tv 'cos you have been taking your pocket money out of the money box on the back :rolling: .....Give me time to find it and answer ! :smiling3:

1/3

Mike,

The others have said it all superb modelling mate.

The others have said it all superb modelling mate.

You got it Paul.Aha, the reason for that "silly millimeter" is now evident, allowing the adjacent door to open w/o binding. Some excellent workmanship here. PaulE

Wow, amazing attention to detail. I know from bitter experience that the camera lens likes to emphasise any imperfections and I can’t see any so amazing job.Having built a fitters vehicle some time ago, I had at the time obtained another kit of a different variant. This has sat in the store for all this time alongside the Zelda.

After getting the Chieftain ARV underway I needed something to fill in during the periods when that build grew a bit stagnant.

So out came several kits from AFV's to aircraft, and back they went, and out they came again, and again untill I finally settled on the old Academy I.D.F. M113 fitters vehicle.

First order of the day was to get out the research and this is well covered in the Desert Eagle Publishing book by Michael Mass & Adam O'Brien #9 Part 1 - Fitters.

And also Eduard came into the job with a couple of etch sets plus there is going to be some scratchbuilding.

After looking at the kit I decided to replace the floor with etch, first the moulded tread was removed, the sides sanded the interior sanded along with locating points being removed and yes - sanded.

To make the job easier I decided that the interior was going to be built/scratch and this means the hull top will be left off, and that I would work from rear to front, this also means I can work on the hull top without damage.

Number one on the build was the fuel tank. I rubbed down all the moulded detail, had a look at a couple of walk around web sites and gathered the information I needed for the tank/pipes and fittings. These were all made from rod, pewter sheet, copper wire and odds and sods.

As you can see there is still some pipe work still to be completed (the floor is removeable) before moving onto the tool box and ammunition box storage on the right side.

More later,

Mike.

Thank youWow, amazing attention to detail. I know from bitter experience that the camera lens likes to emphasise any imperfections and I can’t see any so amazing job.

Mike

Legal Notice

scalemodelling.co.uk is a privately operated online discussion forum. All content posted by members reflects their own views and opinions and does not necessarily represent those of the forum owners or administrators. While reasonable efforts are made to moderate content, no responsibility is accepted for user-generated material. By using this site, you agree to comply with UK law and the forum rules.