G

Guest

Guest

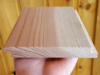

Crikey. Just the OSB for mine is touching half of that amount. Then there's the actual timber for the frame, the cladding, insulation, plasterboard, breather membrane, vapour barrier, EPDM roof, doors, windows. More garden room than shed though I guess.But i think i could get the wood direct from a sawmill (we have a few up here) for about £1000.