I have watched a couple of videos on youtube but I'm still not clear.

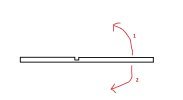

See below an example, this is the cross section of a PE part I need to bend. Forgive my drawing skills on Microsft Paint.

My PE parts show a dent on one side.

Now, is there an accepted way that it will always have to be bent (A) as per 1, (B) as per 2, (C) it doesn't matter, or (D) it will have to be bent one way but it could be 1 or 2 and I will need to "think" to know which one.

Thank you.

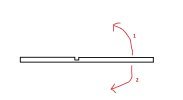

See below an example, this is the cross section of a PE part I need to bend. Forgive my drawing skills on Microsft Paint.

My PE parts show a dent on one side.

Now, is there an accepted way that it will always have to be bent (A) as per 1, (B) as per 2, (C) it doesn't matter, or (D) it will have to be bent one way but it could be 1 or 2 and I will need to "think" to know which one.

Thank you.